Home

Introduction

Our customers benefit from our experience in automation & controls, refurbishment, upgrades, onsite calibration and engineering services including CE certification and documentation according to German Maschinen Richtlinie for test equipment. Together with our strong partner we can build new equipment from small fuelcell benchtop tester up to MW electrolyser test stations.

Test Station Refurbishment

We offer refurbishment of test stations, including electrical cabinet, process loops and software. We can exchange broken and old components, or exchange the entire technical hardware with state of the art components. Included in our service is a new CE certificate, electircal drawings, P&ID and manuals, which makes the refurbished machine pretty much a new machine. A completely refurrbished machine is aproximately 30 % less expensive compared to a new machine.

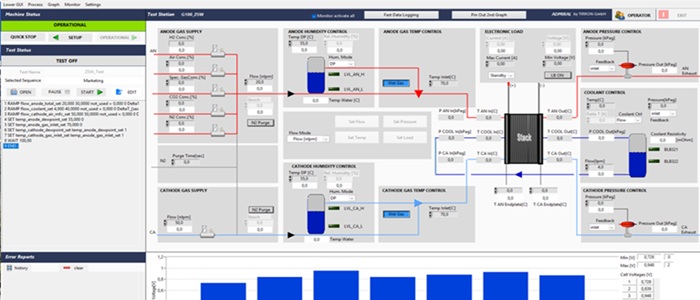

Test Station Automation

Since the year 2000 we automate test stations, mainly in the fuel cell industry.

Our automation system focuses on safe, reliable, realtime and accurate operation of complex systems. Our architecture consists of a realtime PLC, including safety controller and a LabVIEW based user interface running on a test station PC.

Custom Projects

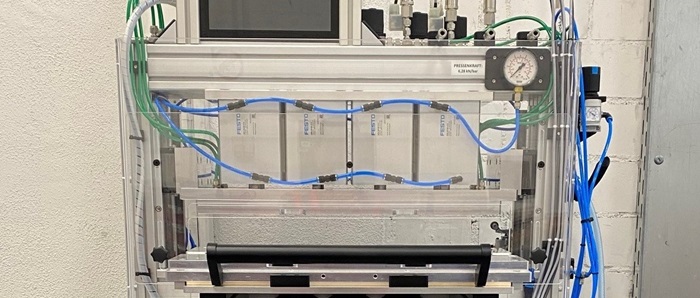

Talk to us if you need specialized equipment, or if you have unfinished projects, that need automation and controls.

Custom projects that we have done in the past include:

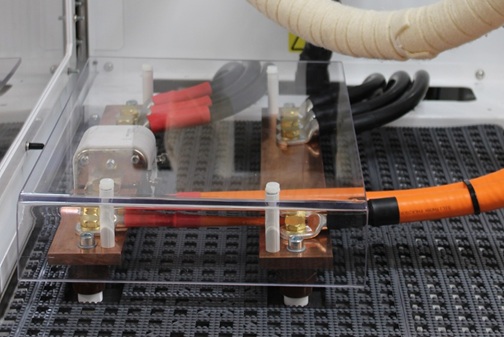

- fuelcell single cell leaktester

- di-water pressure booster up to 90 bar

- ATEX exhaust gas treatment for electrolyser

- IO box for de-centralized data aquisition

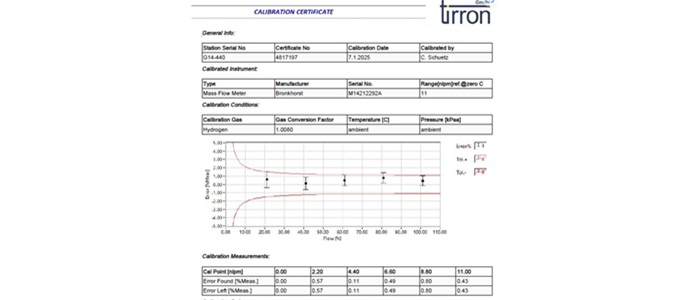

Test Station Service

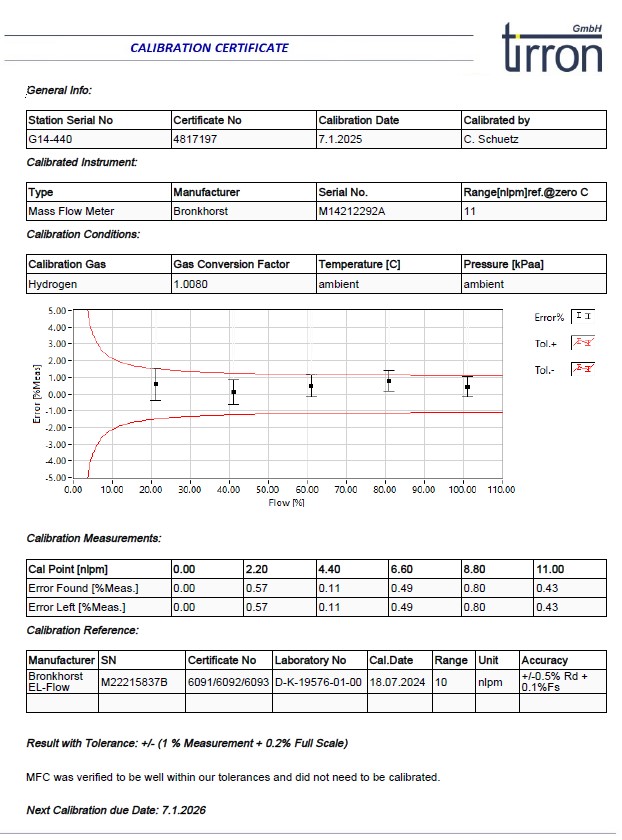

With our yearly calibrated ISO 17025 equipment we calibrate onsite:

- mass flow from 20 nmlpm up to 8000 nlpm

- temperature up to 100 degC

- pressure up to 20 barg

- cell voltage monitor

- elektronik loads up to 1000 A

- power supplys up to 1000 A

Our onsite maintenance and service package includes:

- safety matrix check

- leack check

- pump maintenance

- filter maintenance

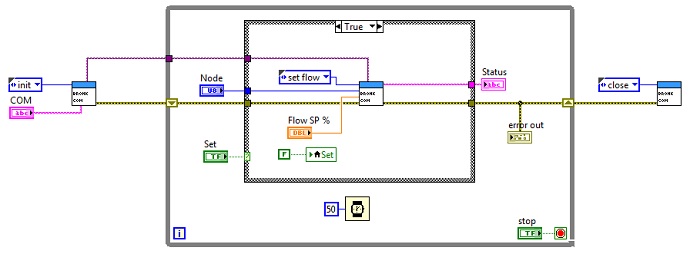

Test Station Upgrades

Test station requirements change constantly. Regardless of new safety regulations, better sensors/actuators or simply the need for higher power. We can upgrade test stations to match changed specifications.

- Load Upgrade

- GI-DAQ Replacement

- MFC Configuration Upgrade

- Third Party Device Integration

- Software Upgrade

- Humidifier Technology Upgrade

DI-Water Booster

Electrolyser testing requires refilling of process loops with electrolyte. Trending research aims for high pressure systems to eliminate the need for a first stage H2 gas compression system.

Our di-water booster system can feed several electrolyser test stations.